Студопедия КАТЕГОРИИ: АвтоАвтоматизацияАрхитектураАстрономияАудитБиологияБухгалтерияВоенное делоГенетикаГеографияГеологияГосударствоДомЖурналистика и СМИИзобретательствоИностранные языкиИнформатикаИскусствоИсторияКомпьютерыКулинарияКультураЛексикологияЛитератураЛогикаМаркетингМатематикаМашиностроениеМедицинаМенеджментМеталлы и СваркаМеханикаМузыкаНаселениеОбразованиеОхрана безопасности жизниОхрана ТрудаПедагогикаПолитикаПравоПриборостроениеПрограммированиеПроизводствоПромышленностьПсихологияРадиоРегилияСвязьСоциологияСпортСтандартизацияСтроительствоТехнологииТорговляТуризмФизикаФизиологияФилософияФинансыХимияХозяйствоЦеннообразованиеЧерчениеЭкологияЭконометрикаЭкономикаЭлектроникаЮриспунденкция |

Match the word combinations.

Translate the Participles constructions into Russian. Composing of the following components, methods used in modern engineering, requiring the drivers effort, performing by spring bolts, fixed at both ends, attached to a member of the body, consisting of a compressed-air cylinder, lubricating steering system, placed on the rear axle, equipped with rack-an-opinion steering

Translate the following words and word combinations from Russian into English. Рулевое колесо, пружинная система, рулевой механизм, огромный успех, комплектовать, сайлент-блок, задний мост, располагать, цилиндрическая прямозубая передача, рулевая колонка, ход поршня, амортизатор, трение, зафиксированный, гидроусилитель управления, червячный механизм, пыльник рулевой тяги, маятниковый рычаг, закрепляя болты, автомобили оборудованные усилителем, не прилагая большого усилия, контролируя рулевое управление, методы используемые в современной инженерии, двигатель закрепленный на опорах, обеспечивая контроль над управлением, смазывая его движущиеся части, защищая от пыли. Ask questions to the following sentences. 1. Steering wheel, steering column and steering-gear case are the parts of steering system. (What?) 2. Spring suspension is performed by spring bolts supported in a bushing. (How?) 3. For heavy lorries one spring cannot be expected to meet all the requirements. (Why?) 4. The operation of steering system should not require great effort. (Why?) 5. Pneumatic cushion is used in modern automotive engineering. (What kind of …?)

Translate the following sentences into English. 1. Большинство автомобилей оборудованы усилителем руля. 2. В рулевое колесо вмонтирована подушка безопасности. 3. АвтоВАЗ выпускает машины с электроусилителем рулевого управления. 4. Автомобили без усилителя сложны в управлении для начинающих водителей. 5. Автомобиль с неисправностями в рулевой системе небезопасен. 6. Руль в современных автомобилях имеет травм безопасную конструкцию. 7. Почему исправная рулевая система очень важна? 8. Какие усилители рулевого управления предпочтительны для больших авто? 9. Исправная рулевая система обеспечивает безопасную езду. 10. Почему водители иномарок прилагают меньше усилий к рулевому колесу? 11. Назовите основные элементы рулевой системы? 12. Кузов размещается на раме и туго крепится. 13. Рамы бывают различных типов: хребтовая, лонжеронная и х-образная. 14. Рамная конструкция обычно применяeтся на большеeгрузных авто. 15. Автомобильные компании производят разные авто на одинаковых шасси. 16. Уход за кузовом автомобилей очень важен. 17. Шасси представляет собой совокупность движущихся элементов автомобиля  TEXT IV 1. Read and translate the texts. Brakes Every motor vehicle is to be equipped with two independent brakes. Each brake must be able to stop the vehicle within the shortest distance. Above all, braking of a vehicle depends on the friction between tyres and road surface. Brakes operate most efficiently when they are applied so that the wheels do not quite lock but continue to turn without slipping on the road. The force of the slipping friction between tyres and road is much smaller than the brake power. In addition, the wheel loses all of its road-holding ability and tends to skidding. In order to utilize the whole wheel load, i.e. the total ground adhesion of a vehicle for its braking, all vehicles are now equipped with all-wheel brakes.

Almost without any exception, motor-vehicle brakes are "shoe-type brakes." Depending on their actuation, a difference is made between foot brakes and hand brakes. The foot brake is also called service brake, while the hand brake is called parking brake. However, the parking brake should not be considered as an inferior brake.

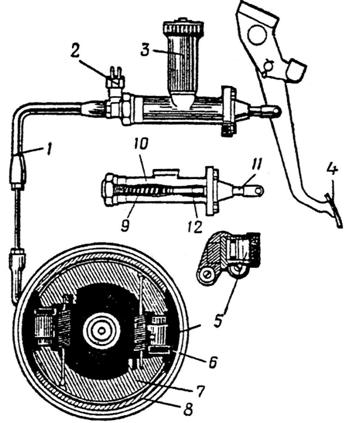

Hydraulic brake Гидравлическийтормоз 1 — pipe / трубопровод; 2 — stop-signal switch / включательсигнала; 3 — reservoir / бачок; 4 — pedal / педаль; 5 — wheel brake cylinder / колесныйтормознойцилиндр; 6 — brake spring / стягивающаяпружина; 7 — brake shoe /тормознаяколодка; 8— brake shoe lining /тормознаянакладка; 9— spring /пружина; 10— master brake cylinder / главныйтормознойцилиндр; 11 — rod / шток; 12 — piston / поршень; According to their mode of operation, the brakes are classified as mechanical (rod-linkage and cable-operated) brakes, hydraulic brakes (oil brakes), air brakes. Depending on their action on the front or rear wheels or on the drive, the brakes are classified as front-wheel-brakes, rear-wheel brakes or transmission brakes respectively. Besides, brakes are classified as external-contracting or internal-expanding brakes. Modern motor vehicles are almost exclusively equipped with internal-expanding brakes acting on all the wheels of the car.

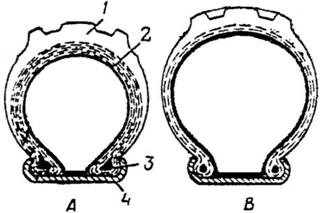

A— high-pressuretyre / шина высокого давления; B — low-pressuretyre / шина низкого давления; 1 — tread / протектор; 2 — tube / камера; 3 — bead / борт(ик); 4— rim / обод

Universal Shaft In most vehicles with rear-wheel drive and with the engine arranged in the front end of the chassis, a propeller shaft is required leading to the rear end. It is flexibly connected to permit the upward and downward movement of the rear axle casing. The flexibility of this shaft is achieved by the cardan or universal joint; it is a joint permitting the transmission of a rotary motion while simultaneously vibrating. Universal joints made of metal are placed in sleeves or metal housings to be filled with special grease. Instead of the universal joint it is possible to use rubber-vulcanized fabric disks, the so-called dry-disk joints (hardy disks), especially in lorry (truck) manufacture. For lorries (trucks) with a long wheel base, the universal shaft isfrequently subdivided. Its front part is supported in the frame and in line with the transmission; its rear part is designed as an oscillating universal shaft in dry-disk or universal joints. The rear end of the universal shaft is connected with the drive shaft of the rear-axle drive (rear-axle step-up gearing) by a universal or dry-disk joint. Differential Gear Since thecrankshaft of the engine rotates in the longitudinal axis of the vehicle it is required to turn this sense of, rotation at right wangles for the driving wheels. In most cases, this is performed by a bevel-gear drive. A small bevel gear— the driving pinion — is connected to the short shaft of the final drive and it meshes with a large bevel gear, the so-called spur bevel gear. The permanent step-up ratio between these two bevel gears ranges from approx: 1:4 to 1:6 for passenger: cars and from 1:5 to 1: 12 for lorries (trucks) depending on the particular size of the vehicle. The so-called differential gear is housed in the final drive and it is connected to the spur bevel gear. It has been provided to accomplish the following purpose. When a car travels around curves, the distance travelled by the outside wheel is greater than that travelled by the inside wheels; i.e. the outside wheels revolve faster than the inside wheels. This, however, would not be possible if the driving wheels were attached to a one-piece axle. Therefore, the two wheels are attached to separate axles but they are connected to each other by the differential gear in such a way that they may turn at different speeds and even in opposite directions. If one driving wheel is turned toward the front with the drive shaft jacked up and the engine at stand-still, the other wheel turns in opposite direction via the differential gear at the same angle. Locking one of the two wheels with the engine running causes the other wheel to rotate at twice the speed. In order to avoid wheel spinning and to ensure the drive under all circumstances, especially the drives of cross-country, cars are equipped with a differential lock. With this device, the differential action is temporarily eliminated and the rigid drive of the two wheels made possible. The locking devices can be operated either manually or become effective automatically whenever considerable differences in speed should occur. Axle Drive The axle shafts are half-axles with their front ends supported in ball bearings in the axle housing. The rocking lever for the torsion bar suspension acts on the external side of the axle bracket; here, the torsion bar suspension is located in the longitudinal direction of the car and .contains simultaneously the shock absorber in the rear torsion bar bearing. The front-wheel drive offers advantages with respect to construction and driving technique. The whole driving unit, i.e. engine, transmission, drive shafts and wheels, has to be arranged on the smallest space. Due to the fact that a universal shaft is not required, it is possible to build the chassis very low, resulting in a very, low position of thecenter of gravity and in good road — holding properties. On slippery roads and in curves the car pulled by the front wheels tends less to swerving than the car pushed by the rear wheels. The wheels are suspended independently. At the top the wheel is held by the transverse spring and at the bottom by a wishbone. The drive shaft is located in the center between two wheel suspension components. TEXT V

1.Vocabulary to be remembered:

2. Read and translate the text: CHASSIS Frame The frame of the motorcar supports all the driving units such as engine transmission and rear axle; besides, it is meant for the attachment of the spring system, front axle and steering system. In assembled condition, all these components are called the "chassis." The body is placed on the frame and tightly bolted. The simplest type of motorcar frame has two side members made of cold-rolled channel-section steel. They are connected by a number of cross members which support the radiator and the engine. The most important requirement of the frame is that it shall be stiff and strong enough to resist the twisting and bending forces to which it is subjected, particularly when the vehicle is travelling over tough roads. Since the introduction of the independent wheel- suspension by transverse springs etc., the shapes of the frames have changed considerably For some modern passenger cars and buses, the frameless construction, the so-called "chassisless body" is now used. In this case, the body is designed so stiff that it replaces the frame. All the units, such as engine, transmission, axle casing, springs and steering, otherwise arranged on the frame, are attached to the body. Therefore, only a limousine or bus body can be used for a chassis less construction since only these bodies may be built sufficiently resistant to torsion due to their particular type of construction. A special type of frameless construction is the platform construction; in this case, the frame has been replaced by a corrugated continuous bottom plate. This construction can be used only for independent wheel suspension with front-wheel drive or rear-mounted engine since it has no oscillating universal shaft. It combines the advantages of light-weight construction and the possibility to attach various bodies. In addition, the continuous bottom plate offers a good protection against dirt and it permits convenient clearing.

|

||||||||||||||||||||||||||||||||||||||||

|

Последнее изменение этой страницы: 2018-05-10; просмотров: 728. stydopedya.ru не претендует на авторское право материалов, которые вылажены, но предоставляет бесплатный доступ к ним. В случае нарушения авторского права или персональных данных напишите сюда... |